-

Home

-

Company

-

-

Jiangsu Xinhua Alloy Co., Ltd.

Jiangsu Xinhua Alloy Co., Ltd. is a high-tech enterprise specializing in the production, research and development of special alloy materials. It is a well-known enterprise in the field of special nickel base alloy materials. In 2004, it passed ISO9001:2008 quality management system certification.

-

-

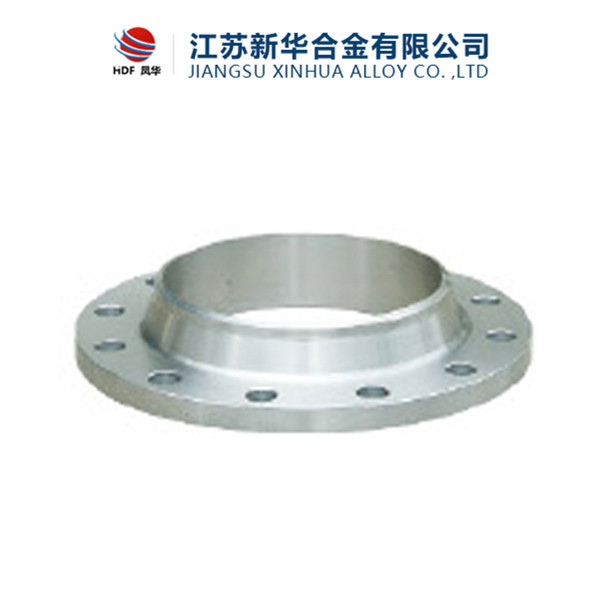

Product

-

-

Jiangsu Xinhua Alloy Co., Ltd.

Jiangsu Xinhua Alloy Co., Ltd. is a high-tech enterprise specializing in the production, research and development of special alloy materials. It is a well-known enterprise in the field of special nickel base alloy materials. In 2004, it passed ISO9001:2008 quality management system certification.

-

-

Equipment

-

News

-

-

Jiangsu Xinhua Alloy Co., Ltd.

Jiangsu Xinhua Alloy Co., Ltd. is a high-tech enterprise specializing in the production, research and development of special alloy materials. It is a well-known enterprise in the field of special nickel base alloy materials. In 2004, it passed ISO9001:2008 quality management system certification.

-

-

Service

-

Contact